Initial situation:

The production halls of the Berlin Siemens plant, where gas turbines are assembled, were equipped with outdated mercury steam lamps. In addition to the immensely high power consumption of up to 1,000 watts per unit, the luminaires were varied light colors. The maintenance was extremely complex and costly. The individual luminaires often failed, causing an increase in the unpleasant operating noise. The disruptions to operations caused by the failure-prone hall lighting were no longer acceptable to Siemens.

Customer request and order:

The outdated ceiling lights in the hall were to be converted to modern LED technology. According to customer requirements, the output per unit should be at least 700 lux. It was also important that individual areas of the hall could be switched with different light intensities with the provided dimming function. A quick replacement of the lights and connection technology during operations should be guaranteed.

The solution from BRAUN:

The special challenge of this project was that a high degree of prefabrication had to be achieved. On the one hand, the dropping of small parts during the new installation could have damaged the turbines underneath. The hall with a mounting height of approx. 24 m was very high, making it difficult to reach the existing luminaires.

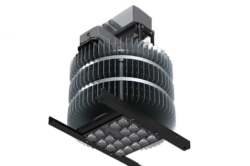

BRAUN successfully converted the hall to the latest LED lighting technology using BigTAB 4er clusters. In accordance with customer requirements, a radio solution, with which all luminaires could be controlled, programmed, and dimmed, was implemented. Since no new cables had to be laid for this, the conversion time was correspondingly short and the cost-benefit ratio from the customer’s point of view was ideal. In the end, 1,000 lux was realized instead of the 700 lux required, SIEMENS was satisfied placing follow-up orders with BRAUN.